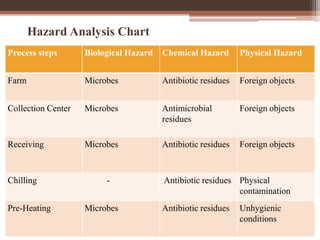

It is generally recognized that the production of cheeses with desirable organoleptic char-. The traditional inspection and quality procedure in order to prevent the hazards in the cheese product.

Haccp Implementation On Cheddar Cheese

Although the cheesemaking process for some cheeses will.

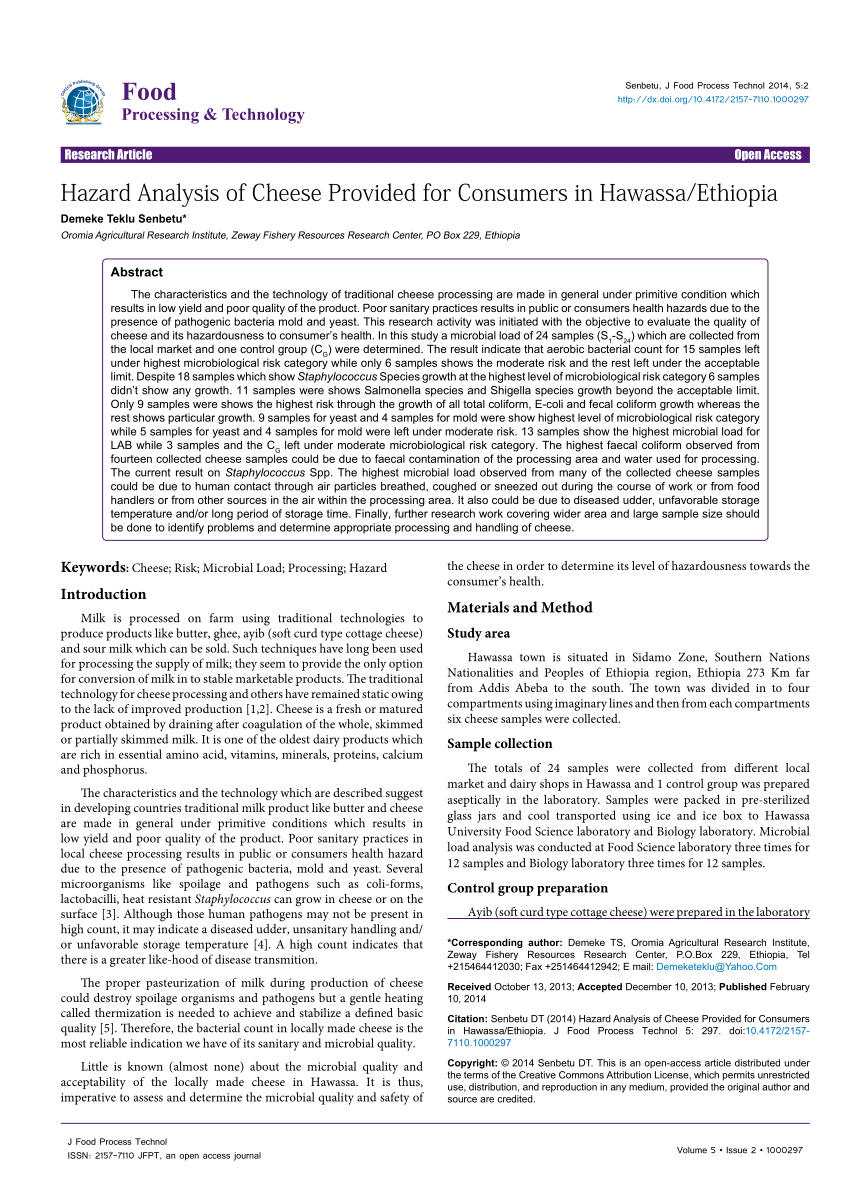

. In a recent study on Monte Veronese cheese an Italian PDO semi- hard cheese made with raw milk Staphylococcus aureusnumbers in cheese were higher than the104CFU g-1limit in 78 of samples 1. Hazards in Cheesemaking biological pathogen growth inadequate acidification improperly cleaned equipment biofilms on equipment contaminated water cheese mites chemical cleaning chemicals allergens contaminated water physical hazards cheese harp screen. Almost all the processors 967 disposed solid waste by bush burning causing environmental pollution.

Whereas for dairy cheese there is 100 years of food safety science. When the shape parameter varies between 2 and 5 the corresponding distribution is nearly bell-shaped. To evaluate the current methods of analysis on hazards that appear during the processing and control procedures used in the plant.

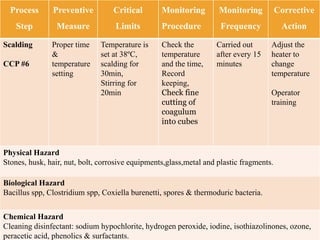

Acta Scientiarum Polonorum Technologia Alimentaria 93 2010 335 RESULTS AND DISCUSSION Development of UF white cheese HACCP plan 1. The Hazard Analysis and Critical Control Point HACCP is a preventive and systematic method used to identify assess and control of the hazards related with raw material ingredients processing marketing and intended consumer in order to assure the safety of the food. Keywords hazard analysis critical control point HACCP pasteurisation sterilisation contamination Tweet.

Axis that is parallel to the data line. HAZARDS IN RAW MILK CHEESES. The key determinant for the safety of raw milk cheese is the microbiological quality of the raw milk.

Weibull hazard analysis plot for cottage cheese stored at 4C. Results of the study show that hazards in soy-cheese processing include physical chemical and occupational apart from microbial types. Further analysis was undertaken to determine if it was possible to apply the findings of the risk assessments to other cheeses which lie within the same moisture category.

Thaw in refrigerator so cheese wont lose moisture. The concept of Hazard Analysis of Critical Control Points HACCP is a preventive structured systematic and documented approach to ensure food safety Bu-chanan 1990 Motarjemi Kaferstein Moy Miyagawa Miyagishima 1996. This is the area that has the least science support for these products.

Freeze pieces of a half-pound or less. In this study a methodological. Use moisture-proof and airtight wrapping.

The hazard analysis critical control point system HACCP is a widely used tool in the food industry and recommended in the water safety plans WSP approach. The slower the cheese is thawed the. 11 of noncontact surfaces in eight NJ artisan cheese factories.

Brazil two cheese plants 13 10 Barancelli 2011. The aim of this study was to design a HACCP plan for implementing in a Gouda-type cheese-making. Implementation of the Hazard Analysis Critical Control Point HACCP system.

17 of 243 noncontact surfaces Menendez. Microbial hazards occur most frequently but chemical hazards such as antibiotics and physical hazards such as metal contamination must also be considered. Pathogens from raw milk may.

Line b represents lhc data line. National Center for Biotechnology Information. Tips for Freezing Cheeses.

Staphylococcus aureuswas the most frequent pathogen associated with cheeses from raw or unspecified milk in food-borne disease. 7 28 of non food contact surfaces in cheese plants. This intersecting value is then the shape parameter.

Here well identify hazards relevant to cheese making in general terms. To set up a specific HACCP plan for this small-scale cheese plant. Hazard Analysis 30 1 Typical hazards in cheesemaking 30 2 Identification and control of hazards in milk production and cheesemaking steps 31 Identification of Critical Control Points CCPs 52 How to Identify CCPs 52 Critical Limits for CCPs 52 Documentation and Records 53 Verification of HACCP-based Procedures 53.

To document the HACCP plan in order to demonstrate the. Raw milk can directly contaminate cheese with pathogenic organisms if it is not pasteurized See Section 94. Both liquid and solid wastes were generated during the production process.

The tool identifies measurable parameters and provides templates to monitor and record variation to help cheesemakers understand how changes in raw materials and processes impact the sensory characteristics consistency and quality of their cheese. Line a represents the shape parameter line. Cheese is subjected to chemical analysis for a variety of reasons such as to ascertain its composition for nutritional purposes to ensure its compliance with standards of identity to assess the efficiency of production or as an index of quality see Ref.

Identify potential safety hazards in a cheesemaking process create a HACCP plan to show how safety hazards can be minimised at each stage of a cheesemaking process Purpose This activity will prepare students for making cheese safely. It is also known that actively growing cultures can inhibit the growth of pathogens. Freeze quickly and store at 0 F for two to six months.

Keep in mind that traditional cheeses often have pH values between 46-52. Buildings and facilities must be of sound construction and. The purpose of the Penn State Extension Food Safety Plans for Small-Scale Cheesemakers is to assist small-scale and raw milk cheesemakers in conducting hazard analyses of their processes to ensure they are producing the safest product possible and to meet the requirements of the Food Safety Modernization Act FSMA.

There are several programs used in UF white cheese pro-duction line.

Hazard Analysis Of Cheese Processing Steps Download Table

Pdf Control Of Haccp System Efficiency In Cream Cheese Production Semantic Scholar

Hazard Analysis Of Cheese Processing Steps Download Table

Process Safety Chemical Engineering Michigan Tech

Haccp Implementation On Cheddar Cheese

Critical Control Points In Haccp System Set Up In Cream Cheese Production Download Table

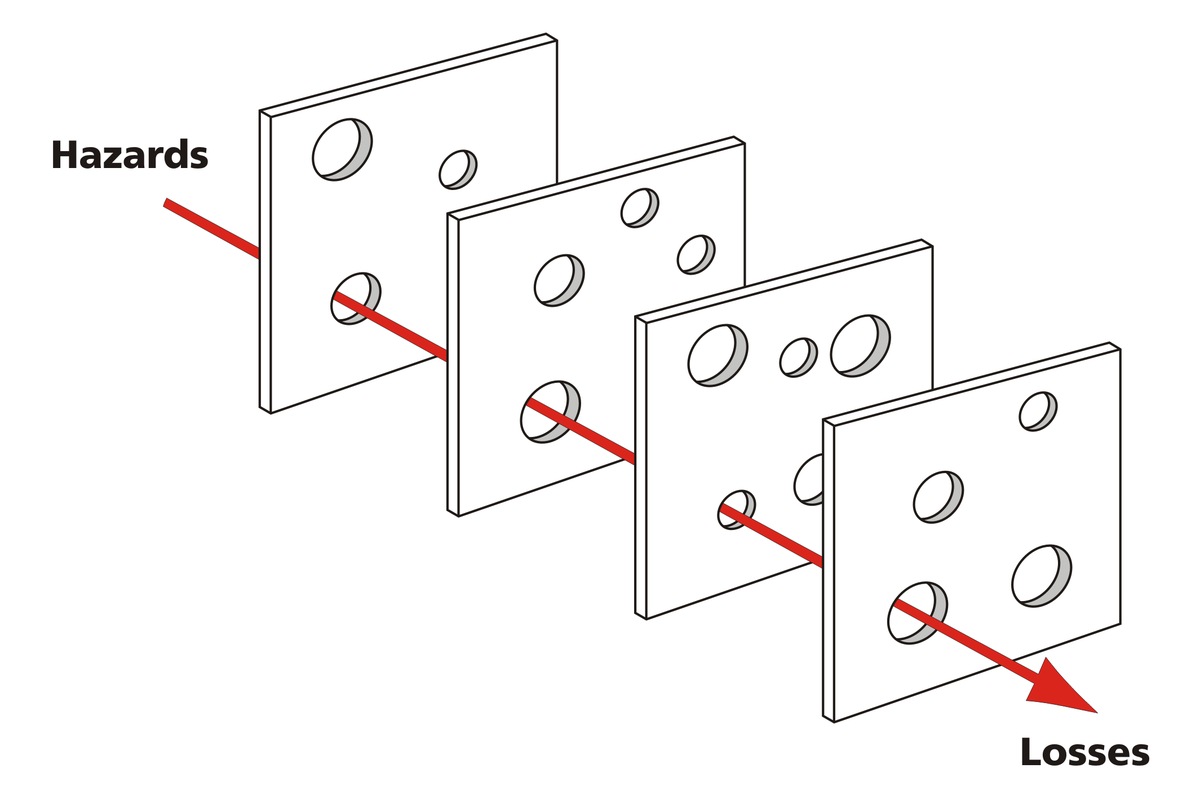

A Swiss Cheese Model For Reducing Biases In User Research By Biswajeet Das Ux Collective

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

Implementation Of The Hazard Analysis Critical Control Point Haccp System To A Dairy Industry Evaluation Of Benefits And Barriers Semantic Scholar

Critical Control Points In Haccp System Set Up In Cream Cheese Production Download Table

Pdf Implementation Of Hazard Analysis Critical Control Point To Feta And Manouri Cheese Production Lines Semantic Scholar

Determinants Of Implementation Of Hazard Analysis And Critical Control Point Project In Four Selected Gouda Cheese Processing Firms In Rwanda Semantic Scholar

Schweizer Kase Modell Wikipedia

Pdf Hazard Analysis Of Cheese Provided For Consumers In Hawassa Ethiopia